HISTORIES AND VALUES

LUBIAM is today one of the few Italian companies still run by the family of its founder, Luigi Bianchi, who left his village in the province of Mantua - San Michele in Bosco - at the age of 16 to go to Turin to learn all the secrets of tailoring. He wanted to become a tailor, to ennoble the family tradition of his father Paride and grandfather Giuliano, tailor-barbers from house to house in the villages of the countryside.

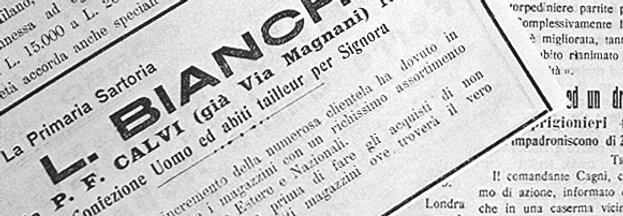

In 1911, Luigi crowned his dream by opening the "Primaria Sartoria Luigi Bianchi - Confezione Uomo e abiti e tailleur per Signora" (Primary Tailoring Luigi Bianchi - Tailoring for Men and Ladies' Suits and Dresses); thanks to his enthusiasm and great passion for craftsmanship, he managed to set up a successful business that has since established itself as Made in Italy excellence in high-end menswear, recognised in Italy and abroad. In the first twenty years after its foundation, the business evolved from a family-run workshop to a company with over 300 employees.

This exceptional transformation took place thanks to the introduction of the Fordist model in the company in 1929, through a long process of specialisation and innovation - strongly desired by Edgardo Bianchi, Luigi's eldest son - aimed at improving production times and guaranteeing a top-quality result with the same characteristics as a made-to-measure product. From 250 employees in 1933, the company grew to 400 in 1936 and with them to INDUSTRIA CONFEZIONI LUIGI BIANCHI.

In 1938 the new headquarters were inaugurated in what is now the Valletta Paiolo district, where the head office is still located today.

In 1939 the brand LUBIAM was born, an acronym for Luigi Bianchi Mantova, to underline the deep bond with the land of origin.

After the war, the 50s and 60s saw a rebirth with the economic boom, as well as the launch of major advertising campaigns, involving TV, radio and television.

The Seventies marked the entry into the company of the new protagonists of the third generation: Giuliano and Luigi Bianchi Jr.

From this moment on, the company's history is a continuous succession of events and successes, including gradual expansion, first in the U.S.A. and gradually in all the countries of Europe and the world, until reaching China and Japan.

In the 1990s, the company underwent a global restructuring process to give the brand new development prospects.

Evolving further under the guidance of the fourth generation of the Bianchi family, the company celebrated its centenary in 2011: a constant commitment to research, a drive towards innovation, continuous experimentation, a passion for craftsmanship and a desire to offer garments of absolute quality are the values that have enabled the company to reach such a milestone, demonstrating its ability to continually reinvent itself and its products without forgetting its history.

The third and fourth generations of the family still work side by side: the members of the Board of Directors are the siblings Edgardo, Giovanni, Giulia and Gabriele with their father Giuliano Bianchi, President of the company.

MADE IN ITALY – MADE IN MANTUA

Lubiam has a huge advantage over other companies because

it can boast more than a century of experience in tailoring

men’s luxury garments under the same family.

The key to its success lies in its identity as a family business

and the values handed down to the business by different

generations. Indeed, contrary to other companies - which

have chosen to relocate production - the Bianchi family has

tenaciously continued to invest in the Made in Italy label and

chosen to keep its original production site in Mantua, enhancing

it with modern machinery and the experience and professionalism

of highly qualified personnel.

In the main Factory in Viale Fiume, the process of the garments

realization occurs from beginning to the end.

Here the inspirations and the ideas are trasformed into product,

which is subject to careful quality control.

The gestures and artisan procedures, optimized and developed

on an industrial level, resulting in a series of steps, which

allow to obtain at the end a perfect tailored garment.

The warehouse that contains up to 120.000 items, is handled

in a highly efficient manner to ensure the best delivery time.

CORPORATE SOCIAL RESPONSIBILITY

A FAMILY FRIENDLY COMPANY - Human resources have always been a key factor for Lubiam in terms of development. Since the company was founded, welfare and attention to people have been part of the philosophy of the Bianchi family, which has been at the helm of the company for four generations. Edgardo Bianchi explains: <<We firmly believe that human resources are our most valuable asset. Unlike other companies, we have chosen to maintain the original production site in Mantua, enriching it with state-of-the-art equipment and investing in training to enhance the experience and professionalism of the highly qualified personnel who contribute to our success on a daily basis. Today more than 300 employees work at Lubiam and we are proud of the positive climate that characterises the company, which has always been family-run.>>Precisely in order to enhance its internal resources, Lubiam has always invested in Welfare activities in support of its employees: the Family-Work Award won in 2009 was a formal recognition of a way of acting that has been handed down over the years and which also creates added value at a social level. Among the policies implemented are: flexible working hours and a high percentage of part-time work (which for women is close to 30%); the company canteen - the first in the Province of Mantua - and the 'Ida and Edgardo Bianchi' company crèche, which is certainly one of the most appreciated of the services offered to staff. All of these activities have a positive impact on the working environment and productivity. In addition, a strong bond has been created with the local community, which for generations has respected and supported the work of Lubiam, recognised as an ethical and Family Friendly company, a point of reference for the Mantuan economy and the history of Made in Italy.

LUBIAM AND ART - The link with the Mantua area and the love for art and culture have always been strong in the brand's DNA:

a vocation that has been translated into many activities.

Among the most recent, the fruitful collaboration with A scuola di Guggenheim, the educational section of the Peggy Guggenheim Collection in Venice, with projects dedicated to schools that have involved over 1200 students in each edition.

From 2016 to 2019 the company collaborated with Mantova Creativa and the Palazzo Ducale Museum Complex, supporting "Scultura in Piazza", a festival that brought international artists such as Hidetoshi Nagasawa, Eduard Habicher and the brothers Lucio and Beppe Perone to Mantua to create large works specifically for the Piazza Castello space.

After being exhibited in Piazza Castello for a year, each of these sculptures was then transported and installed in the Viale Fiume headquarters, further enriching the heritage of works already present within the company.

Again in collaboration with the Complesso Museale Palazzo Ducale di Mantova, the following project was carried out in 2019

"Fashion marries art - A capsule collection for the Giulio Romano exhibition":

a special selection of Luigi Bianchi garments was created to celebrate the major exhibition "Con nuova e stravagante maniera"

organised by the Palazzo Ducale Museum Complex in Mantua in exceptional collaboration with the Musée du Louvre in Paris.

LUBIAM GOES GREEN - Right from the start Lubiam implemented various initiatives to minimise its already low ecological impact.

It is something Lubiam holds dear: over the years its consumption

of energy and water has been drastically reduced and waste has been disposed of and recycled by means of separate collection; many parts of the company facilities have timed energy-saving LED illumination to avoid wasteful consumption.

The canteen on the company’s premises helps to reduce travelling at lunchtime, avoiding the use of cars.

Nowadays our facilities are even more up to date regarding environmental sustainability and the use of energy, thanks to the installation of a large, latest generation photovoltaic system (3000m2), integrated into the roof. 2020 will see the initiation of several new projects designed to reduce use of one-way plastic items: plastic bottles will be replaced by flasks supplied to all employees, and in the field of packaging we have chosen new, ecofriendly, regenerated

plastic garment bags. The raw material used to produce them derives from virgin plastic production scrap. This safeguards

the environment by re-using existing plastic, thereby avoiding new gas emissions from oil, and at the end of its useful life the garment bag is recyclable.